Why impregnation?

Most components from foundries are to some extent porous to gas and liquid.

Most components from foundries are to some extent porous to gas and liquid.

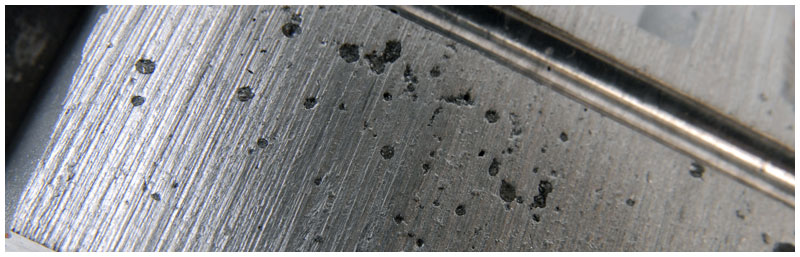

The origin of these flaws lies in the way metals are poured. It is, indeed, at this stage that imperfections such as cracks or porosity occur.

These imperfections are rarely visible to the naked eye. Impregnation is the only permanent way to remedy the water tightness shortcomings of the materials.

The need for ever more complex components and better quality materials at a competitive price have caused foundries to turn the impregnation process as only answer to this question.

Impregnation makes it possible to reach a pressure tightness of 10-6 bars to helium with resistance to very high pressure (800bars). In many cases, impregnation is an integral part of the program.